|

|

The

Platinum Cannon Shipwreck |

|

| Joe

Champion | David

Hudson(semi-technical lecture) | David

Hudson(made easy) | 20th

Century Alchemy(3 Chapters)

|

| The Platinum Cannon Shipwreck | The Mango Metal Report(3 chapters) | Bookstore | |

|

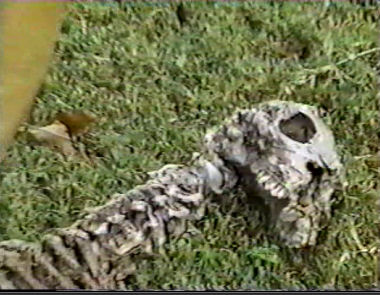

Jack picked me up early for breakfast and explained what steps we would follow on the first demonstration. To convince me that we did not have contaminated ("salted") chemicals, we stopped at a feed store where we bought a 50 pound bag of sodium nitrate (NaN03) off the shelf. This chemical is sometimes referred to as nitrate of sodium. Next I we stopped by a convenience store for a bag of every day charcoal. The other component required for the demonstration was a mineralized black sand. Black sand is a portion of ore with the sand, silica and silicates removed. In this particular case, we used a mineral from a tailing pile, the waste from a mill after they have removed the mineral for which they are mining. The black sand we used came from a closed precious metal refinery. Billions of tons of this waste exist within North America. I will address this in more detail later. The black sand was analyzed by fire assay process to determine the amount of gold and silver present. It is normal to find trace amounts of gold and silver associated with tailing piles. Milling is usually done by mechanical processes which ordinarily lack high efficiencies. The process used in determination of gold and silver quantity is called a fire assay. This procedure consists of taking a chemical flux, mixing it with the ore and placing it in a high temperature clay crucible in a small electric oven at 1,000°C for two hours. In this phase, most of the metals are reduced and collected inside lead which was included in the flux. The metals are then easily separated when poured into a conical (not to be confused with witchcraft) mold. When cool, the lead is removed and cleaned of all slag, a glassy residue, and placed in a cupel. A cupel is a little cup which was first reported in Egypt around 5,000 B.C. originally, chemists prepared the cupel from bone ash, a process in which bones (in the case of the Egyptians, human bones) were burnt until they were reduced to ashes. These ashes were then mixed with a small amount of moist clay, molded and allowed to dry. A similar process is used today in the production of cupels, except a chemical compound has been substituted for the bone ash. At any account, the lead is set in the cupel and placed in the electric furnace at 900° C. When the lead becomes molten, it soaks into the base of the cupel, like water into a sponge, leaving the precious gold, silver and the PGMs on top in their pure state. This was the process used by Keller to determine the amounts of new gold and silver he gained during his experiments.

(Note: All weight and measures reported from point on are in the metric system.) Prior to mixing, Keller used an impact mill grinder to reduce all compounds to screen less than a 200?mesh size, an approximate fineness of talc. Then he thoroughly mixed the chemicals until they were evenly distributed. At this point, he placed the powder into a one kilogram can, specifically, an empty two and a half pound coffee can. He then placed the can on a smooth, dry surface and ignited the chemicals and mineral with a small torch.

|

|

|

| Joe

Champion | David

Hudson(semi-technical lecture) | David

Hudson(made easy) | 20th

Century Alchemy(3 Chapters)

|

| The Platinum Cannon Shipwreck | The Mango Metal Report(3 chapters) | Bookstore | |

|

Copyright©2014

Globe Merchant |